Nomex Paper (7 mil)

| Properties | Unit | Obtained Value |

| Thickness | mm | 0.234 |

| Width | mm | 910 |

| Substance/Grammage | gm/sqm | 280 |

| Tensile Strength (Unfolded) | ||

| Machine Direction | N/10 mm | 240 |

| Cross Direction | N/10 mm | 275 |

| Tensile Strength (Folded) | ||

| Machine Direction | N/10 mm | 230 |

| Cross Direction | N/10 mm | 272 |

| Elongation | ||

| Machine Direction | % | 25 |

| Cross Direction | % | 70 |

| Electrical Strength (Breakdown Voltage) | ||

| Unfolded | KV | 18 |

| Folded | KV | 16 |

| Thermal Rating | Degree Celcius | 155-180 |

| Colour | Ivory | |

| Peel Strength (Internal) | Good |

Nomex Paper (10 mil)

| Properties | Unit | Obtained Value |

| Thickness | mm | 0.311 |

| Width | mm | 910 |

| Substance / Grammage | gm / sqm | 396 |

| Tensile Strength ( Unfolded ) | ||

| Machine Direction | N / 10 mm | 330 |

| Cross Direction | N / 10 mm | 395 |

| Tensile Strength ( Folded ) | ||

| Machine Direction | N / 10 mm | 320 |

| Cross Direction | N / 10 mm | 380 |

| Elongation | ||

| Machine Direction | % | 38 |

| Cross Direction | % | 65 |

| Electrical Strength ( Breakdown Voltage ) | ||

| Unfolded | KV | 24 |

| Folded | KV | 22 |

| Thermal Rating | Degree Celcius | 155-180 |

| Colour | Ivory | |

| Peel Strength ( Internal ) | Good |

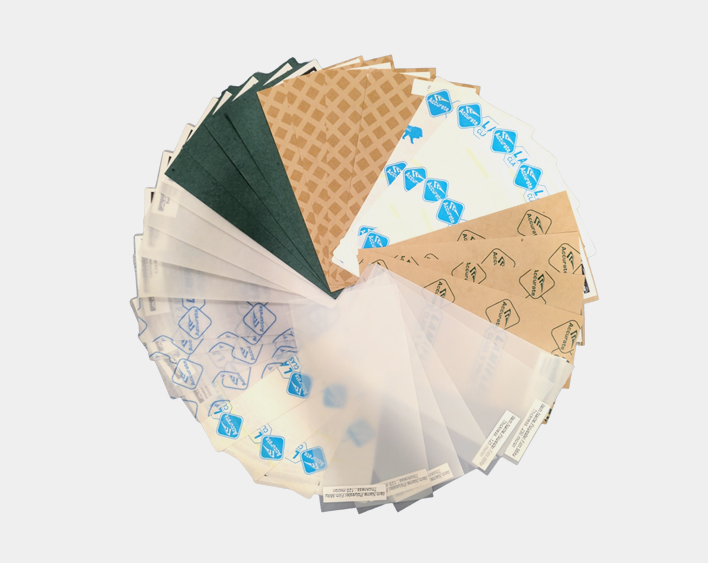

DMD Fleece Paper

| Properties | Unit | Obtained Value |

| Thickness | mm | 0.14 |

| Width | mm | 1010 |

| Substance / Grammage | gm / sqm | 335 |

| Tensile Strength ( No Bending ) | ||

| Machine Direction | N / 10 mm | 272 |

| Cross Direction | N / 10 mm | 208 |

| Tensile Strength ( After Bending ) | ||

| Machine Direction | N / 10 mm | 210 |

| Cross Direction | N / 10 mm | 180 |

| Elongation | ||

| Machine Direction | % | 10 |

| Cross Direction | % | 15 |

| Electrical Strength ( Breakdown Voltage ) | ||

| No Bending | KV | 16 |

| Thermal Rating | Degree Celcius | 155 |

| Colour | Ivory | |

| Bonding Property ( at room temp ) | No delamination |

Diamond Dotted Paper (DDP)

| Properties | Unit | Obtained Value |

| Thickness | mm | 0.125 |

| Width | mm | 100 |

| Tensile Shear Strength | N / mm² | 1 |

| Tensile Strength | ||

| Longitudinal | N / mm² | 80 |

| Transverse | N / mm² | 50 |

| Shrinkage | ||

| Longitudinal | % | 1.2 |

| Transverse | % | 2 |

| Breakdown Voltage | ||

| Dry | KV | 1.2 |

| In Oil | KV | 8 |

| Electrical Conductivity of Aqueous | ?S / cm | 80 |

| Moisture Content | % | 7 |